Difference between revisions of "Installation and Integration"

JimStewart (talk | contribs) |

|||

| Line 103: | Line 103: | ||

=Navigation= | =Navigation= | ||

[https://web.fnal.gov/collaboration/DUNE/SitePages/FD%20Installation%20and%20Integration%20Working%20Group.aspx Back to Working group page] | [https://web.fnal.gov/collaboration/DUNE/SitePages/FD%20Installation%20and%20Integration%20Working%20Group.aspx Back to Working group page] | ||

| + | |||

| + | =Action items= | ||

| + | [https://dune.bnl.gov/wiki/Installation_and_Integration/ActionItems#2._Underground_space Action item page] | ||

Revision as of 13:21, 26 October 2016

Contents

Integration and Installation

Far Detector Integration

The interface between the Conventional Facilities and the cryogenic/cryostat with the Far Detector are a major component of the integration group for DUNE.

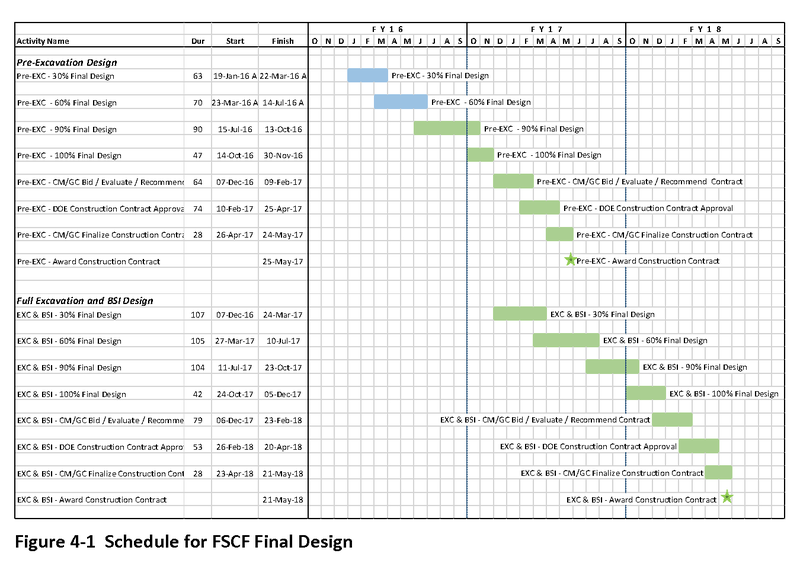

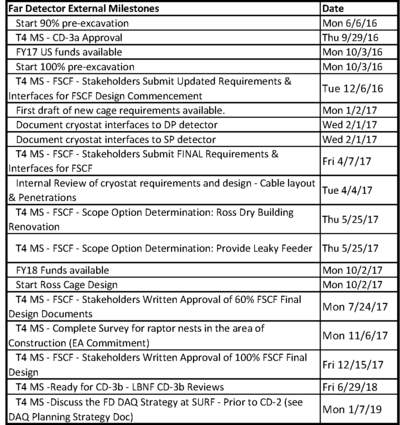

The table of external milestones connected to the CF design process is listed below:

Key Documents

- 100% Preliminary design for Buildings and Site Infrastructure and Excavation from Arup USA

- BSI Preliminary Design Report (2015-08-24_BSI-100 Percent PDR.pdf, 12.6 MB)

- BSI Surface Design Drawings (Surface Binder.pdf, 16.0 MB)

- BSI Underground Drawings (Underground Binder.pdf, 34.2 MB)

- EXC Drawings (Excavation Drawings.pdf, 30.8 MB)

- EXC Preliminary Design Report (EXC_100_PDR Issue 0.pdf, 76.9 MB)

- LBNF BSI Pre-Excavation 60% Final Design Submission

- Comprehensive Logistics Plan

- LBNF EXC Pre-Excavation 60% Final Design Submission

- LBNF BSI Pre-Excavation 90% Final Design Submission

- LBNF EXC Pre-Excavation 90% Final Design Submission

Logistics

The general plan for how materials will be transported to and within SURF is found in the SURF Logistics Assumptions document.

The Comprehensive Logistics Plan describes in some detail how the shaft usage will need to be planned. It also contains on page 9 the description of the detector needs which DUNE defined for the logistics study.

3.1.3 Time Projection Chambers The cryostat time projection chamber (TPC; see Figure 6) comprises the following components:

- Anode Plane Assemblies (APAs) – 150 ea. 2.3m × 6.3m × 0.1m

- Four APAs per shipping container (see Figure 7)

- Estimated weight of 3,600kg per container

- Cathode Plane Assemblies (CPAs) – 200 ea.

- 2.3m × 3m (1400 m2)

- Four CPAs per shipping container

- Field cage (2,000m2)

- Readout electronics and racks – 75 ea.

- High V oltage (HV) system

The main elements are shipped in containers 1.3m × 2.8m × 7.3m (APA’s) and 0.5m × 2.5m × 3.8m (CPA’s) and 0.6m × 0.8m × 2.1m (racks). Most items will be configured in skid-size containers.

Other Key documents and events related to the SURF logistics are:

Surface Facilities

Ross/Yates Shaft Hoisting

The basic information related to hoisting is summarized in DOCDB 328 Far Site Shaft Hoisting Assumptions and Parameters.

Reference documents in DOCDB 328:

- Draft set of requirements for a new cage

- Interface discussion presentation describing load delivery

- List of Cryostat components and how to deliver through shaft

Underground facilities

The far site conventional facilities is using the information from the Drift Study for referencing the maximum size objects that need to be accommodated by the surf infrastructure.

Interface Management

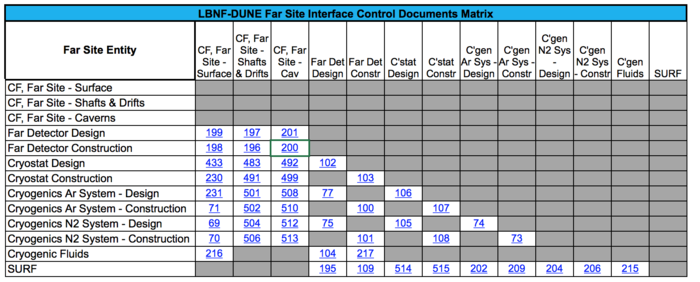

The interfaces between Conventional Facilities and the Far Detector are documented through a series of Interface Control Documents that are agreed upon by both LBNF and DUNE. The ICDs themselves generally only identify the interface and then refer to a separate key document to describe and define the interface.

LBNF Systems Engineering webpage for interface management

Interface Control Documents

- CF Far Site Surface <--> Far Detector Design

- CF Far Site Shafts and Drifts <--> Far Detector Design

- CF Far Site Caverns <--> Far Detector Design

- CF Far Site Surface <--> Far Detector Construction

- CF Far Site Shafts and Drifts <--> Far Detector Construction

- CF Far Site Caverns <--> Far Detector Construction

Single-Phase Far Detector Installation

Cryostat internal installation

Material Handling

Roof access is primarily necessary during electronics cabling and deployment of the FC panels. An areal platform will be used when work at heights is required. One possibility which was used quite successfully are the Palazzani Industrie platforms. Palazzani areal platforms

Data Sheet for a small platform (1m wide) areal lift